Stainless Steel Wire Mesh Manufacturers

– Applications of Wire Mesh Rolls

Filtration and Separation

Removes impurities & contaminants from liquids and gases.Employs precise aperture sizes for particle separation.

Vastly used in pharmaceutical and chemical industries for filtration.

Food and Beverage Processing

Filters liquids like juices, syrups and oils, thereby, ensuring superior clarity and extended shelf life.Domestic Usage: Stainless steel mesh finds common applications in domestic settings, including SS tea strainers, SS mesh for windows, and mosquito nets.

Textile Industry

Used in Fabric Filtration and Cleaning by removing impurities.Classify and segregate fibers and yarns based on their sizes or weight.

Industrial Applications

Filters petroleum products in the petrochemical industry.Screens and separates minerals in the mining industry.

Used as a conveyor belt in many industries.

Air Conditioning System

Used to filter out dust, pollen and other airborne particles.Architectural and Decorative Uses

Intricate patterns and its sleek appearance make them a suitable choice for decorative screens, railings and partitions.Exceptional Performance and Versatility from a Trusted Wire Mesh Supplier

Exceptional Strength and Durability

Renowned for exceptional strength and durability, our wire mesh products are ideal for a wide range of demanding applications.

Corrosion Resistance

High-grade stainless steel and rigorous quality control in manufacturing is the reason, our products display exceptional corrosion resistance in harsh environments.

Customizable Solutions

We tailor our products to meet the unique demands of each application, thus, providing exact solutions.

Siriram Filters is a trusted name in wire mesh India, offering high-quality solutions as leading mesh manufacturers in India. As experienced stainless steel wire mesh manufacturers and SS wire mesh manufacturers, we supply precision ss mesh, ss mesh filter, and custom filtration products for diverse industrial applications.

Mumbai Wire Mesh | Delhi Wire Mesh | Chennai Wire Mesh | Kolkata Wire Mesh | Rajkot Wire Mesh | Surat Wire Mesh | Ahmedabad Wire Mesh | Vadodara Wire Mesh | Hyderabad Wire Mesh | Bangalore Wire Mesh | Jaipur Wire Mesh

SS Wire Mesh Manufacturer in India

What is ss wire mesh?

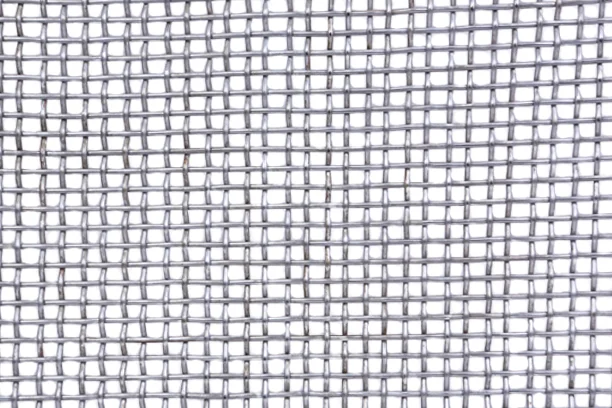

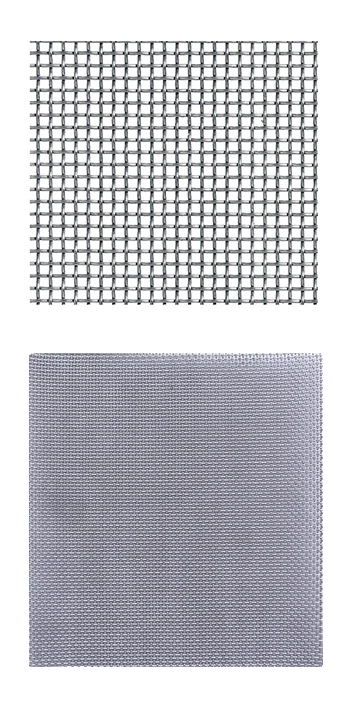

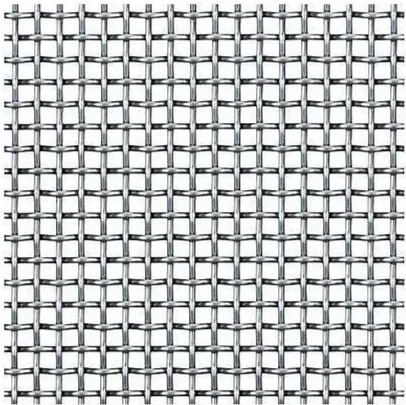

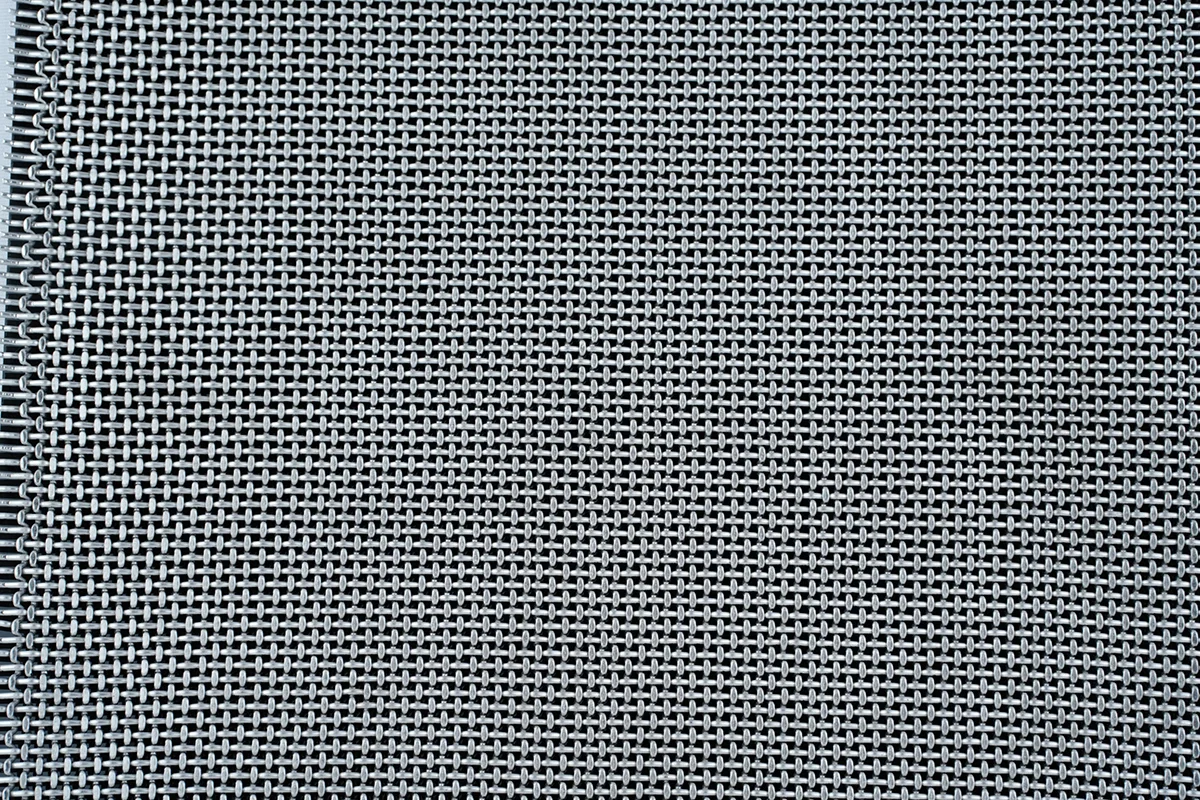

SS wire mesh is a durable and versatile woven material made from stainless steel wires. It is commonly used in filtration, screening, and industrial applications due to its corrosion resistance, strength, and long lifespan.

What are the benefits of stainless steel wire mesh?

Stainless steel wire mesh offers excellent durability, resistance to rust, and the ability to withstand high temperatures. It ensures precise filtration, requires minimal maintenance, and is widely used in industries like chemical, food processing, construction, and mining.

Where is ss mesh commonly used?

SS mesh is widely used in filtration systems, sieving, fencing, architectural design, and protective barriers. Its high tensile strength and anti-corrosive properties make it suitable for both industrial and household purposes.

How is stainless steel wire mesh different from other meshes?

Unlike plastic or mild steel meshes, stainless steel wire mesh is more durable, resistant to harsh environments, and offers better performance in filtration and screening. It provides a longer service life and consistent results in demanding conditions.

Can ss wire mesh be customized for specific applications?

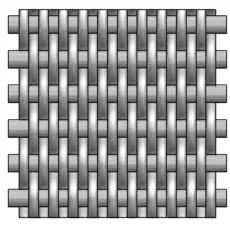

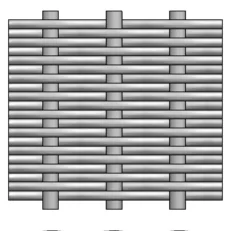

Yes, ss wire mesh can be manufactured in different sizes, thicknesses, and weaving patterns. Whether for fine filtration, structural support, or decorative purposes, stainless steel wire mesh can be tailored to meet specific industry requirements.

How do I choose a reliable wire mesh supplier?

A reliable wire mesh supplier should have proven industry experience, consistent product quality, and the ability to offer customization. Look for suppliers with advanced manufacturing facilities, strict quality control, timely delivery, and strong after-sales support.

What types of products does a wire mesh supplier provide?

A professional wire mesh supplier offers stainless steel wire mesh, woven wire mesh, fine mesh, wire mesh fabric, and customized filtration products. Many suppliers also provide fabricated mesh components for industrial and commercial applications.

Why is Siriram Filters a trusted name in wire mesh India?

Siriram Filters is a well-established brand in wire mesh India, known for manufacturing high-quality ss mesh and filtration products. As experienced mesh manufacturers in India, we focus on precision weaving, material quality, and reliable supply for industrial applications.

What wire mesh and filter products are manufactured in India by Siriram Filters?

As leading stainless steel wire mesh manufacturers and a trusted wire mesh filter manufacturer in India, we produce ss wire mesh, ss mesh filters, woven wire mesh, and custom filtration solutions for pharmaceuticals, chemicals, and petrochemical industries.