Fill form to download brochure

High-Performance CPF Candle Filters Manufacturer & Supplier

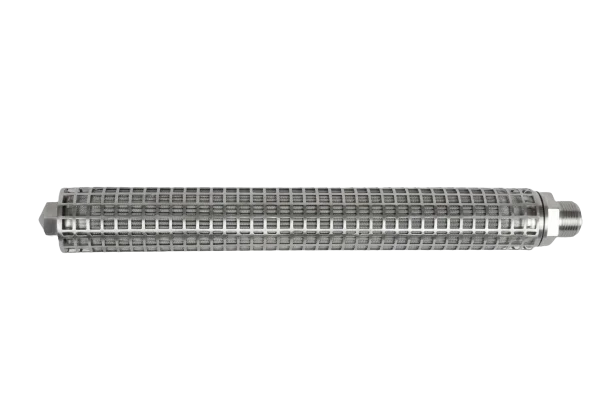

CPF candle filters, often referred to as pleated candle filters, are specialized filtration elements that are designed to remove impurities and contaminants from polymer melts during the manufacturing process. Siriram Filters, being a reputed manufacturer & supplier of SS candle filters in India, understands the critical role that filtration plays in this process and our polymer candle filters stand as a testament to our commitment to excellence.

Exceptional Filtration for Impeccable Polymer Products : These filters are ingeniously crafted to meet the strict demands of the polymer industry, thereby, ensuring the highest quality standards for your end products. Using the cutting-edge manufacturing facilities at Siriram Filters, we are able to produce candle filters with pore sizes ranging from 5 microns to 80 microns, utilizing non-woven sintered metal fiber and Dutch twill weave. Our expertise extends to addressing diverse industrial filtration needs that encompass intermediates, pre-polymers, final filtration as well as spin packs.

Types of CPF Candle Filters

Leading cpf filter manufacturer, Siriram Filters has two main types of Polymer candle filters-

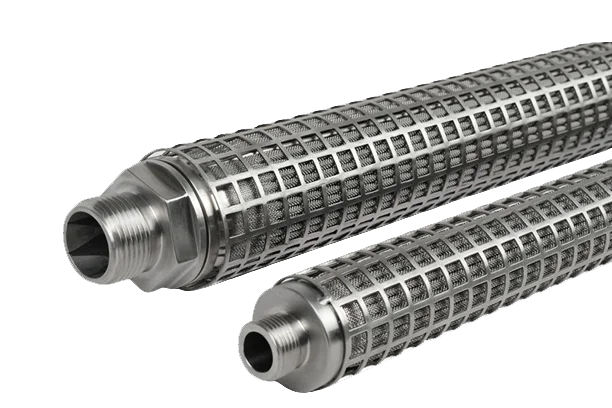

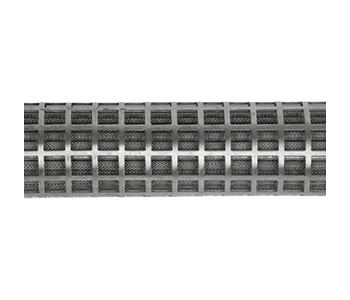

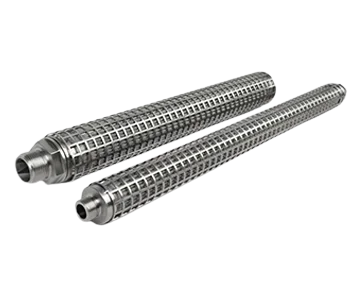

Pleated Wire Mesh Candle Filters

Pleated wire mesh candle filters offer more filtration area and have a greater capacity to hold dirt due to their unique design of pleating. The pleating process increases the surface area of the filter, therefore, allowing it to capture more contaminants.

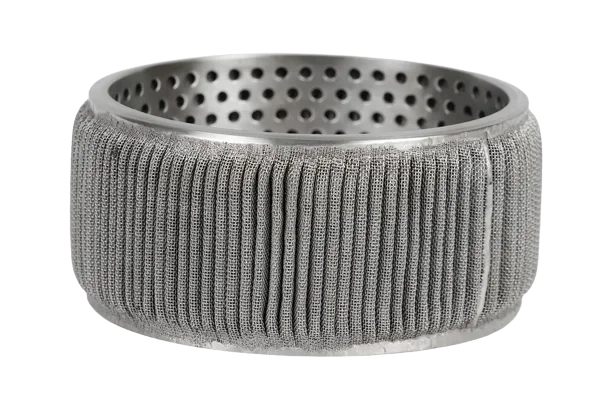

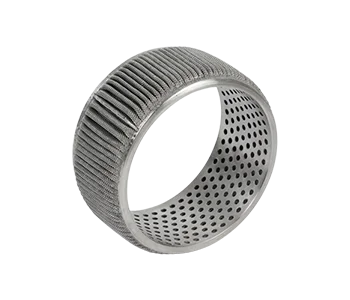

Pleated Sintered Fiber Candle Filter

Pleated sintered fiber candle filters are manufactured from high-quality stainless steel fibers of varying lengths and diameters. The fibers of these SS candle Filters are sintered together at high temperatures to create a porous structure that is both strong and durable. Pleated sintered fiber candle filters are ideal for applications wherever high purity is required, which means the filters are able to capture very fine contaminants.

Advantages of SS Candle Filters

Siriram Filter’s CPF filters are not just ordinary filtration solutions, they embody the pinnacle of advanced engineering and unparalleled quality. As a top supplier and manufacturer of SS candle filters in India, our filters boast a plethora of advantages that easily set them apart from conventional filters, including the incorporation of filter belts for enhanced filtration efficiency.

Exceptional Filtration Efficiency

Siriram Filters stands as a distinguished CPF candle filter manufacturer, bringing exceptional expertise in filtration technology that can filter out the minutest of contaminants so that your polymer products are free from impurities at the same time, meet the strictest quality standards.

Unwavering Consistency

Maintaining consistent polymer quality is crucial for product reliability and performance and at Siriram Filters, we ensure that our advanced manufacturing system delivers unwavering consistency in our filters for all your polymer industry needs.

Cost-Effective Solution

By minimizing waste and downtime, CPF filters contribute to long-term cost savings for polymer manufacturers. Because of its extended service life, manufacturers do not have to undergo the process of frequent replacements and maintenance, in turn, optimizing their operational efficiency.

Enhancing Polymer Purity

Polymer filter elements, represented by Siriram Filter's CPF candle filters, stand out as a key contributor that elevates polymer purity in manufacturing processes. These polymer filter elements offer an efficient filtration process, enhancing the overall purity of polymer melts.

Applications of Polymer Candle Filters

Candle filters, like CPF candle filters, showcase remarkable versatility, which is the reason for reaching across a broad spectrum of applications in the manufacturing industry. These filters play a pivotal role in the following industries-

- Polymer Industry

- Petrochemicals

- Textiles

- Plastics

- Pharmaceuticals

- Food and Beverage

Benefits for Polymer Manufacturers

Long-Term Sustainability

With a reputation of being the trusted cpf filter manufacturers, we believe sustainability is the key to our products. Candle filters, like CPF candle filters offer a remarkable service life, thereby, reducing the frequency of replacements and maintenance.

Regulatory Compliance

Maintaining compliance with industry quality standards and regulatory requirements is essential for every polymer manufacturer. CPF filters manufactured by Siriram Filters not only guarantee compliance but also ensure the safeguarding of the reputation of your company.

Customer Satisfaction

Producing consistently high-quality polymer materials leads to increased customer satisfaction, in turn fostering brand loyalty and driving business growth.

Which type of CPF candle filter is right for you?

The best type of CPF candle filter for your application will depend on several factors,

including the type of polymer being filtered, the desired filtration efficiency and the operating

temperature and pressure. This is where the experts at Siriram Filters guide you in choosing

the right CPF candle filter for your specific needs.

Contact us today to embark on a journey of polymer manufacturing excellence with Siriram

Filters, a prominent CPF candle filter manufacturer in India.