Industrial applications, as we all know, form the foundation of innovation and progress. In this race of never ending advancement, certain products play a pivotal role in shaping efficiency, functionality, and precision. One of these would be, wire mesh – an unassuming yet indispensable material that has made it its way into industries, revolutionizing processes and enhancing productivity.

Being one of the prominent wire mesh manufacturers, Siriram Filters has been supplying Wire Meshes to the filteration Industry for over 50 years now. In this article, we are enlightening on the application of wire mesh in various industries, its role in spot welded screens, wire mesh demister pads, SS wire mesh screens, and the innovative Wire Mesh Pack Filters.

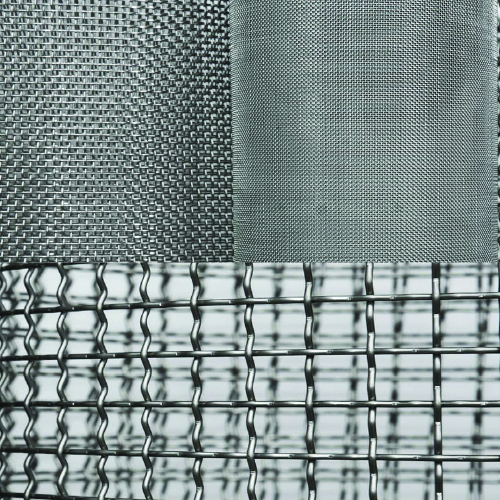

Crafting the Wire Mesh

The most crucial step in an industrial operation is in choosing the right materials. A reputable wire mesh manufacturer plays a pivotal role in choosing the best raw material so that the wire mesh that is being manufactured meets the highest quality standards. By employing advanced techniques and machinery, manufacturers create wire mesh with precise dimensions, and uniform wire diameters. This attention to detail is important for achieving optimal performance in an industry.

Spot Welded Screens

Among the many ways wire mesh is used, spot welded screens stand out as a great example of engineering skill. Imagine a group of wires carefully joined together through welding, creating a strong mesh that can handle pressure and tension. This detailed process involves fusing wires at certain points (spots), making the screens even stronger. Because of this, spot welded screens are perfect for tasks that are in need for controlled particle separation such as in petrochemical, aerospace plastic and metallurgical industries.

Wire Mesh Demister Pads

In industries where it's really important to separate vapour (like steam) from liquids, wire mesh demister pads are the actual heroes. These pads are used in special machines called distillation columns and separation vessels. They use a very tightly woven mesh made of thin wires to catch tiny drops of liquid from the vapour. The design of these pads finds a balance between not causing too much change in pressure and making sure they catch as much liquid as possible. The way the wires are woven together helps the drops of liquid come together, which makes products better and the whole process smoother.

SS Wire Mesh Screens

When dealing with places that can damage things, like really harsh or unfriendly settings, picking the right material becomes a smart decision. SS wire mesh screens are like champions in this scenario because they combine the properties of being resistant to getting rusty and are also really strong in nature. Using stainless steel wires in these screens means they last a really long time, even in really tough conditions. These screens are useful in industries that deal with things like chemicals, making food, and cleaning up dirty water, where protecting against rust and high temperatures is really important.

Wire Mesh Pack Filters

To address the issue on the need for precise industrial filtration, Wire Mesh Pack Filters were introduced. They consist of multiple layers of tightly woven wire mesh that capture suspended particles in the fluid. Their versatility finds application across various sectors such as petrochemicals, pharmaceuticals, and even food processing units. These filters are designed to ensure that the fluid passing through them is clean and free from contaminants. Much like the transformative impact wire mesh has had on creating spot welded screens and demister pads, these filters also show how wire mesh can make a difference in different industries.

Innovative Wire Mesh Applications and Beyond

Beyond Industrial needs, Wire Meshes finds its applications in our day to day life as well. It's used in various places including home security, cooking, gardening, crafts, construction, automotive, and more. As industries evolve, so too does the application of wire mesh, showcasing its adaptability and role as a catalyst for productivity.

Conclusion

Wire mesh is a big deal in industries. Whether it's the detailed spot welded screens, the smart wire mesh demister pads, the tough SS wire mesh screens, or the clever Wire Mesh Pack Filters, they all make things work better, last longer, and be more precise. As a company that is a reputed wire mesh manufacturer, we know how important it is for industries to move forward. In a world where things keep changing, wire mesh is there to make sure everything gets better and brighter, get in touch to explore how we can help you.