From our favourite soft drinks to household cleaning products, most of these items come in PET bottles. But have you ever been caught in a dilemma of what you should do with the bottle once you've finished its contents? If your answer is Recycling, then Bravo! You are absolutely correct!

Recycling: A Sustainable Solution

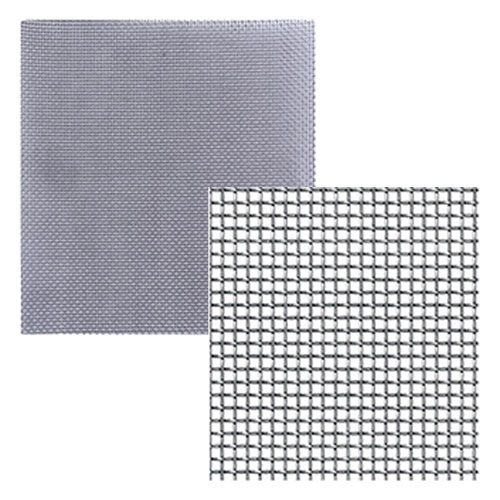

Recycling PET bottles provides a range of benefits, such as energy conservation, reduced emissions and also significant decrease in landfill waste. The process of recycling mainly involves collecting, cleaning and processing of PET bottles into these fibres which are later utilized to create new products. At the heart of this process, lies the challenging task of filtering out impurities and contaminants, a task at which stainless steel wire mesh filters excel.

Reasons to choose SS Wire Mesh Filters

If you are an industry who undertakes recycling of PET Bottles, we have listed down the reasons why you should choose SS Wire Mesh Filters for your Filtration needs.

1. Efficient Filtration:

Stainless steel wire mesh filters are preferred in the primary filtration process as they can efficiently remove unwanted particles from the mix.

2. Durability and Longevity:

Stainless steel's remarkable durability and inherent resistance to corrosion, is the primary reason behind its exceptionally long life.

3. Cost Effective:

When compared to other modes of recycling that ask for segregation of impurities from the PET material, it is important to note that Stainless Steel Wire Mesh Filters are the ones that provide you with a budget friendly solution.

4. Easy Maintenance:

SS Wire meshes are easy to install. They are also easy to clean and maintain, thereby reducing downtime in recycling facilities.

Melting and Extrusion in PET Bottle Recycling

Melting and extrusion are the two important phases of PET bottle recycling, which involves the transformation of collected bottles into recycled PET (rPET) material. In this process, after melting the PET bottle, the major step is to filter out the impurities, such that we obtain only pure and uniform molten PET material. This is where Stainless steel wire meshes emerge as the heroes as it can seamlessly segregate the pure PET material from the contaminants.

These filters are able to effectively segregate pure PET material from its contaminants which gives us the best quality rPET, as the output. The process not only guarantees supreme product quality but also it promotes sustainability throughout. Both, Melting and extrusion are heavily dependent on Stainless Steel Wire Mesh Filters for its effective operation.

Recycled Fibres from SS Wire Mesh Filters

Recycled Fibers which are obtained from PET bottles are used to create various other products such as clothes, footwear, sports equipment etc.. These fibers are obtained after recycling the PET Bottles with the help of Stainless Steel Mesh Filters. Let us understand how SS Wie Filters aid in the process.

The recycling process begins with the collection of PET materials, which are often sourced from discarded PET bottles, which are carefully sorted and cleaned in order to eliminate contaminants, using theSS Wire filters. Next, the cleaned PET bottles undergo shredding, that is to reduce them to smaller pieces, which is to prepare the material for further processing. Following shredding, the PET material is later subjected to a heating process, transforming it into molten PET, commonly referred to as "melt fibers."

An important phase of this recycling journey is the use of Stainless Steel Wire Mesh Filters. The melting of the PET Bottles generates impurities during the process which needs to be effectively eliminated. This is where Stainless Steel Wire Mesh Filters, which are renowned for their durability and resistance to corrosion, are coming to play. Once the filtration process is complete, the purified PET melt fibers are cooled and solidified, taking on a fiber-like structure. The solidified fibers are then cut into desired lengths and can be processed further through spinning, finally resulting in the shape of textile fibers.

These high-quality recycled fibers have numerous applications, from textiles, home furnishings, automotive interiors, nonwoven products, its utilization has employed many industries around the globe. We should note that the usage of Stainless Steel Wire Mesh Filters in the recycling process has ensured the production of pristine and sustainable materials.

Why Siriram Filters are the Best Manufacturers

1. High-Quality Materials:

At Siriram Filters, we manufacture premium stainless steel wire mesh that assures your product's longevity, thereby offering you optimal performance.

2. Customization:

Siriram Filters cater to the needs of industries. We offer a wide range of filter options which can be tailored to different recycling processes.

3. Expertise:

With extensive experience and technical knowledge of manufacturing for over 5 decades, Siriram Filters provide efficient filtration solutions to you that are aligned with the recycling industry's unique requirements.

Recycling PET bottles is a smart and eco-friendly way to deal with the problems that are being caused by their widespread use. Stainless steel wire mesh filters are essential because they help in making the recycling process better by its efficient filtration. Using these filters in the melting and shaping part of recycling also makes everything work better and cleaner, which is good for the environment.