Stainless steel wire mesh, a true marvel of engineering, serves as the backbone of numerous applications, from industrial filtration systems to the simple SS tea strainer found in our kitchens. We know that Stainless Steel Wire mesh is a versatile and an essential material. But what goes into the creation of this unassuming yet highly functional material? Let us find out, as we go through the intricate world of stainless steel wire mesh manufacturing, uncovering the multilevel process that takes raw stainless steel to transform into SS wire mesh.

Selection of Raw Materials

The very first step commences with the careful selection of the finest raw materials. Stainless steel, revered for its exceptional resistance to corrosion and remarkable durability, is where everything begins. The manufacturing process later enters into melting the stainless steel alloy, which transforms into molten marvels ready to be cast into rods or billets.

Wire Drawing

Through a painstaking wire drawing process, these castings are drawn through dies that shrink their diameter gradually. This meticulous procedure ensures that the resulting stainless steel wire is endowed with the exact diameter and mechanical prowess required for the subsequent SS wire mesh roll crafting. This process, known as wire drawing, ensures that the stainless steel wire achieves the required diameter, consistency, and mechanical properties for manufacturing SS wire mesh roll.

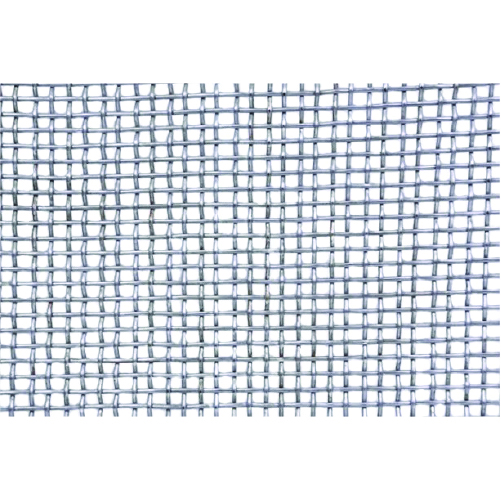

The Art of Weaving Process

The heart and soul of stainless steel wire mesh roll lies in its weaving process. It's here that the mesh's structural pattern, opening size, and strength are carefully crafted. Wire winds onto giant rolls as expert weavers employ various weaving patterns like plain weave, twill weave, or the intricate Dutch weave, tailoring their choices to the required application. The weaving process involves complex interlacing of wires in both the warp and weft directions, which results in a uniform and stable mesh structure.

SS Wire Mesh Manufacturers' Skill

The caretakers of quality, the SS wire mesh manufacturers, play a pivotal role in shaping the standard of the end product. Their skill lies in selecting the right weave pattern, wire diameter, and mesh count, all custom-fit for applications as diverse as stainless steel filter elements and the SS tea strainers. These maestros comprehend the essence of preserving the mesh's structural integrity and unwavering stability while meeting precise industry benchmarks. And at Siriram Filters we take pride to announce that we always meet and exceed the industry expectations as SS wire Mesh manufacturers.

Surface Treatment for a Gleaming Finish

To enhance the longevity of stainless steel wire mesh, various surface treatments are applied. The two major and worldwide accepted treatments are pickling and passivation, two popular procedures that eliminate impurities and ushers in a protective oxide layer, bolstering the mesh's resistance to corrosion. This is especially relevant for everyday household products like SS tea strainers, which withstand the rigors of hot beverages regularly. These extreme heat and diverse environments make it necessary for the product to be built of high quality.

Quality Checks

Before the final stage, SS wire mesh rolls undergo a thorough evaluation process. Rigorous quality control checks encompass measurements of mesh openings, wire diameters, and tensile strengths, safeguarding adherence to industry benchmarks. These steps are crucial to ensure that the final product meets the exacting standards set by both industries and the hands that use them.

From Kitchen to Industry: SS Tea Strainer and Beyond

Observe the SS tea strainer, a simple yet impactful household tool. Crafted from stainless steel wire mesh, it becomes an inseparable part of our daily tea rituals. Its intricate mesh pattern safeguards against stray tea leaves, ensuring our cups are filled with only the liquid beverage. The durability of stainless steel tells that these strainers can withstand repeated use and cleaning without compromising their effectiveness.

Enhancing Industry with Stainless Steel Filter Elements

In a world driven by innovation and precision, stainless steel filter elements emerge as unsung heroes. Just as the tea strainer ensures our cups are free from tea leaf, stainless steel filter elements take on a greater mission – to ensure process purity and efficiency across industries that span from pharmaceuticals to wastewater treatment. With their uniform mesh structure and stainless steel’s built-in resistance to corrosion, these filter elements serve as protectors of quality, safeguarding the integrity of products, processes, and even the equipment.

Conclusion

Stainless steel wire mesh is a wonderful example of how advanced manufacturing processes can transform raw materials into versatile and durable products. As we savor tea steeped through an SS tea strainer or marvel at an industrial filtration system, we're witnesses to a journey that transforms raw materials into products of enduring value. So, the next time you use a SS tea strainer or come across an industrial filtration system, remember the journey that brought this essential material in front of you. Get in touch to explore how we can help you.