Filtration is a vital process in both industrial as well as domestic settings. Filtration ensures the quality and safety of various products and systems as it separates the solid or unwanted impurities from liquid or gas through a porous medium. Wire Mesh Screens are one of the champions of this process. This unassuming yet crucial component is a linchpin of the filtration process, as it is responsible for making substantial contributions to the success of various sectors.

Precision and Customization

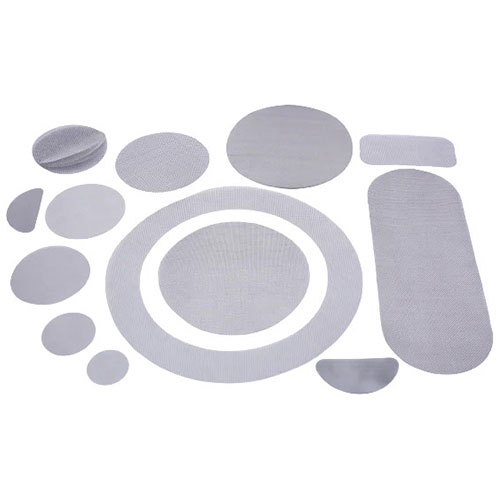

Wire mesh screens are all about precision and customization. These cater to the unique needs of both industrial and domestic filtration. They come in various mesh sizes and configurations, allowing users to fine tune or customize their filtration systems for their specific requirements. Whether it's eliminating fine particles from liquids or gases, wire mesh screens can be adjusted to attain the desired filtration level, while also ensuring optimal performance across different applications.

Durability and Longevity

One of the defining traits of wire mesh screen in filtration is their remarkable durability and longevity. These two traits are more than enough in making them a dependable choice in the world of filtration. They can withstand severe conditions, handle high flow rates and endure abrasive materials without showing signs of wear and tear. This durability not only slashes the maintenance costs but can keep filtration systems running without interruption.

Enhanced Filtration Efficiency

Efficiency is the name of the game in filtration and wire mesh screens are the undisputed champions now. The design of wire mesh screens boasts a more open area, promoting better flow rates while also skillfully trapping particles and contaminants. This unique combination of high flow and top-notch wire mesh screen in filtration is why they are the preferred choice in applications where flow rate and particle removal are non-negotiable.

Chemical Compatibility

Wire mesh screens are crafted from a variety of materials, including stainless steel and alloys, which boasts of outstanding resistance to chemical corrosion. This chemical compatibility is essential in industries where harsh chemicals are involved on a regular basis. Siriram Filters guarantees its customers that their wire mesh screens remain steadfast in their filtration duties without reacting to the substances being filtered, thus ensuring safety and efficiency.

Easy Maintenance and Cleaning

In both industrial and domestic settings, easy maintenance and cleaning are vital. Wire mesh screens are user-friendly, which is, allowing you to remove, clean and reinstall them with ease. Their design and material properties makes the whole cleaning hassle free. Wire mesh screens cut maintenance costs and provides uninterrupted filtration, be it in a massive industrial setup or your domestic abode.

Key Manufacturing Sectors Dependent on Wire Mesh

1. Pharmaceuticals: Maintaining exceptional purity levels is non-negotiable in the pharmaceutical sector. Wire mesh screen in filtration, aid in the production of medicines and drugs as it meticulously removes impurities, thus ensuring that the final products adhere to stringent quality standards.

2. Food Processing: Wire mesh screens are integral to the food processing industry, serving purposes from sieving flour to filtering liquids and separating solids from liquids. They are very much instrumental in upholding product quality and safety.

3. Textile Industry: The textile industry relies on wire mesh screens for its dyeing and printing processes. They guarantee uniform color distribution and also effectively eliminate impurities from dyes.

4. Petrochemical Industry: The petrochemical sector leans on wire mesh screens for the separation of gases and liquids that takes place at varying levels. Consequently, wire mesh screens are an indispensable part of the refinement process.

5. Water Treatment: The delivery of clean drinking water is a top priority and wire mesh screens play a significant role in water treatment plants as it eliminates impurities from the water supplied to households.

Domestic Uses of Wire Mesh Screen in Filtration

1. Window Screens: These screens safeguard your home against unwanted insects and allow fresh air to circulate freely.

2. Gutter Guards: Wire mesh screen in filtration prevents debris and leaves from obstructing your gutters, thereby reducing the need for frequent maintenance.

3. Gardening: Wire mesh screens are valuable in creating garden trellises.

Wire mesh screens are the important components in both industrial and domestic filtration applications. Their precision, durability, sustainability, versatility and ease of maintenance make them the backbone of filtration systems in a range of industries and homes. By choosing wire mesh screen in filtration process, industries and homeowners alike can enhance the efficiency and effectiveness of their filtration processes, ultimately leading to improved product quality, reduced operational costs and more sustainable operations. In a world that relies on top-notch filtration, wire mesh screens prove their mettle by meeting the diverse needs of both industrial and domestic applications. Get in touch to explore how we can help you.