Sealing Gaskets in Polyester Yarn Manufacturing

Polyester yarn manufacturing is an industrial process, where strong, durable polyester yarn is produced through the process of extrusion and stretching. The following are the reasons, of why sealing gaskets are important-

1. Leakage Prevention: There are instances where chemical leakage has occurred because of failure in sealing. Therefore, proper sealing is very essential in order to avoid spillage of harmful chemicals that are used in dyes and solutions, which could lead to contamination and could compromise a controlled and clean environment. To prevent leaks, gaskets, particularly aluminium gaskets, are mostly preferred because of their lightweight nature and corrosion-resistant property.

2. Pressure Control: In yarn manufacturing, extrusion of yarn is one of the major processes. This process takes place at high pressures and elevated temperatures. Here, the molten polymers are forced through tiny openings which turn them into yarn. Therefore, Copper gaskets, renowned for exhibiting high thermal conductivity are the go-to choice when it comes to sealing of the extrusion machinery.

3. Temperature Resistance: Many operations in the yarn manufacturing take place at elevated temperatures. To offer best sealing options, Copper gaskets and aluminium gaskets, as they display excellent thermal conductivity are opted so that the machines function efficiently without losing their sealing properties.

4. Chemical Resistance: As mentioned in the blog earlier, chemicals used in the production process of polyester yarn manufacturing can be corrosive in nature. Good sealing gaskets like aluminium gaskets, being chemically resistant, ensure that they remain intact and effective.

Key Properties of a Good Gasket

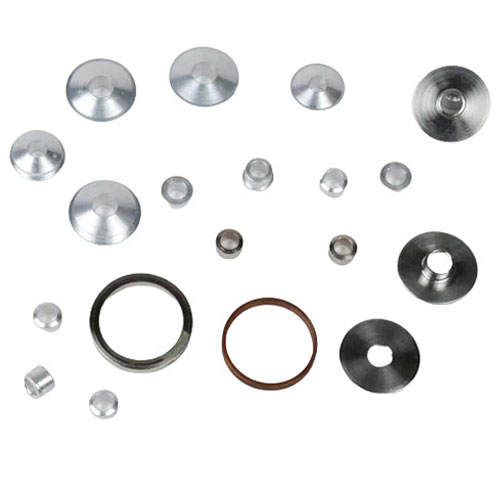

1. Material Used: Copper and Aluminium are the two profound materials used to build gaskets for industrial purposes. Copper gaskets are chosen for their superior thermal conductivity, making them the ideal choice for high-temperature applications. Whereas, aluminium gaskets are appreciated for being lightweight and for their corrosion resistant properties.

2. Resilience: Resilience of a gasket, that is the ability in maintaining its sealing properties even when subjected to varying pressures, temperatures and even when exposed to harsh chemicals is paramount.

3. Precision: Gaskets must be manufactured with precision, in order to match the specific requirements of the equipment they are to seal. Siriram Filters, a leading gaskets manufacturer, prides itself on producing gaskets that offer exceptional precision in their dimensions and shapes.

4. Compatibility: It is important for gaskets to be compatible with the materials they come into contact with. That includes both, the equipment they interact with as well as the substance they are exposed to. Top Gaskets manufacturer, Siriram Filters rightfully assure you that our gaskets are compatible with a wide range of materials and chemicals that are used in the polyester yarn manufacturing process.

5. Ease of Installation: A good gasket should be easy to install, which inturn minimizes downtime during maintenance and replacement procedures.

Sealing Bushes

A Sealing Bush is a simple mechanical component that is used among various industries to provide a tight seal within machineries. Along with sealing, these bushes also aid reduce friction and support moving parts of the equipment..

How is a Sealing Bush related to a Sealing Gasket?

Sealing bushes and sealing gaskets, while they both serve the common purpose of preventing fluid or gas leakage, differ significantly in their sizes and applications. Sealing gaskets are typically flat and compressible and are used in sealing flat surfaces like flanges and joints. Whereas, sealing bushes are much smaller, cylindrical shaped components that focus on sealing, reducing friction and supporting moving parts of the machinery.

To conclude, Sealing gaskets and sealing bushes are both very essential components in the world of polyester yarn manufacturing. They both ensure the integrity of the production process as they are deployed to prevent leaks even at harsh environments. Gaskets manufacturer like Siriram Filters, offer you a range of high-quality, precision engineered Copper gaskets, and aluminium gaskets. These resilient and compatible gaskets aid in efficient working of machineries in the polymer yarn manufacturing process.